UBC team develops greener way to produce clothing fibres

The clothes we wear every day often rely on rayon, a fabric that has long required harsh chemicals to produce. Now, researchers have found a cleaner, more sustainable way to make it.

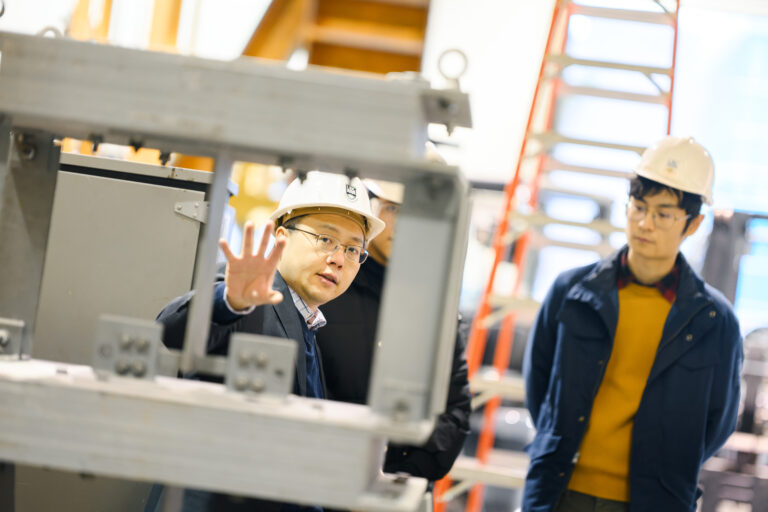

Sustainable rayon can be spun from mechanically treated wood pulp using far fewer chemicals. Photo: Lou Bosshart

A UBC team has developed a cleaner, more sustainable way to produce rayon—a fabric that’s been popular for over a century but has long relied on harsh chemical processes.

Traditional rayon production uses toxic solvents to dissolve wood pulp before spinning it into threads, a process that’s also highly energy-intensive. The new method, developed by UBC faculty of forestry associate professor Dr. Feng Jiang and doctoral student Huayu Liu, uses microfibrillated cellulose (MFC)—hairlike strands made by mechanically grinding down wood pulp. Instead of dissolving all the pulp, the researchers dissolve only a small amount to act as a natural glue, helping the MFC strands stick together and spin smoothly into continuous threads.

By dissolving only part of the cellulose, the process cuts solvent use by up to 70 per cent, eliminates several chemical-heavy pulp-purifying steps, and reuses all solvents in a closed-loop system, making it much gentler on the environment.

“Cellulose fibres like rayon are renewable and biodegradable, but the way they’re made hasn’t always been sustainable,” said Dr. Jiang. “We wanted to change that.”

Next, the team plans to scale up production from the lab and are partnering with Kwantlen Polytechnic University’s fashion design program to test textile applications.

Interview languages: English (Jiang, Liu), Mandarin (Liu)

Featured Researcher

Huayu Liu

PhD student, Faculty of Forestry